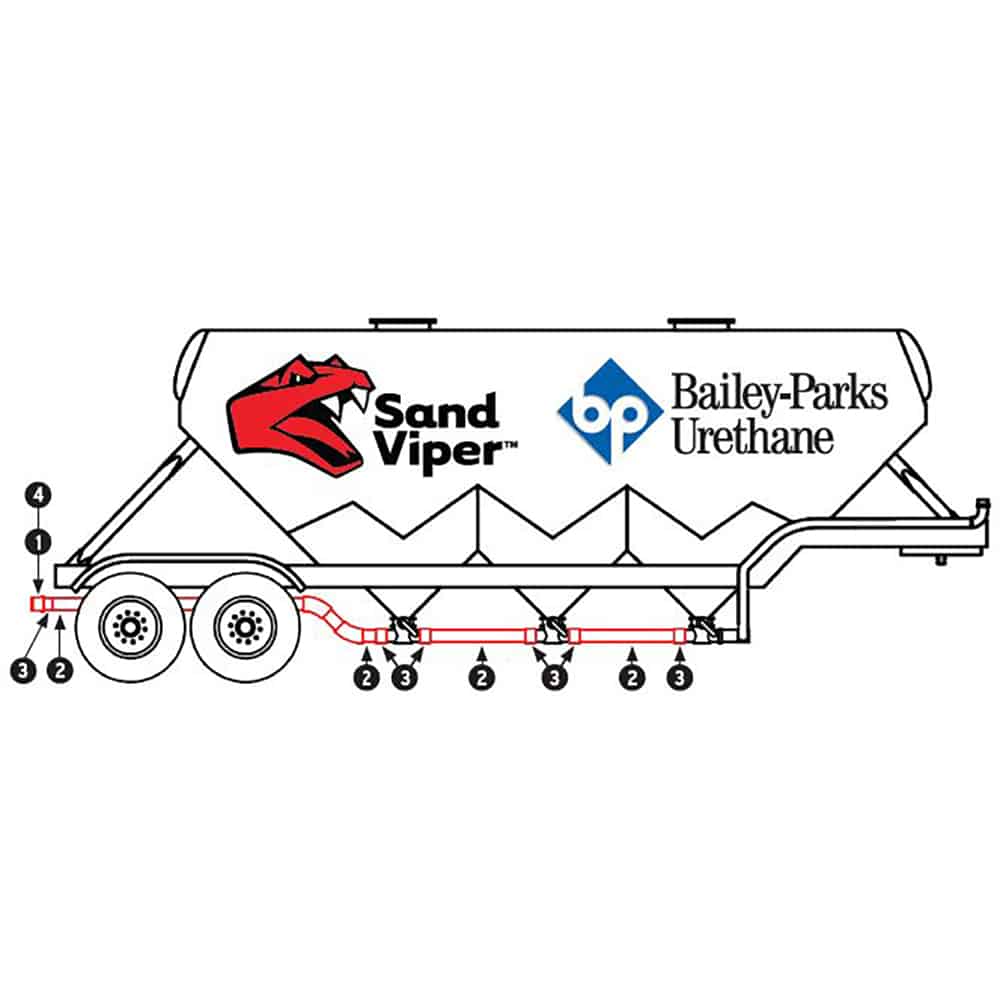

Sand Viper® Frac Sand Transport System

The Bailey-Parks Sand Viper™ piping system is a long-lasting polyurethane piping system originally designed to replace the aluminum pipes on trailers that transport fracking sand.

Incredibly wear-resistant, urethane lasts significantly longer than plain aluminum or steel in harsh conditions like those encountered in the oil, gas, and mining industries. The Sand Viper Pipe is lined with a specialized composite urethane that has enhanced self-healing features so that it is optimized to resist intense abrasion such as that caused by frac-sand.

Advantages for Frac Sand Transport Systems

The Sand Viper system can be adapted for a wide variety of applications involving the transport of caustic materials, such as those administered by the waste management, Coke, Tyconite, Slurry (wet & dry), and nearly all abrasive industries including the growing Frac Sand industry. The Sand Viper system is highly customizable, and includes several components, such as lined aluminun pipe, which can be used to build a complete piping system to fit nearly any specifications.