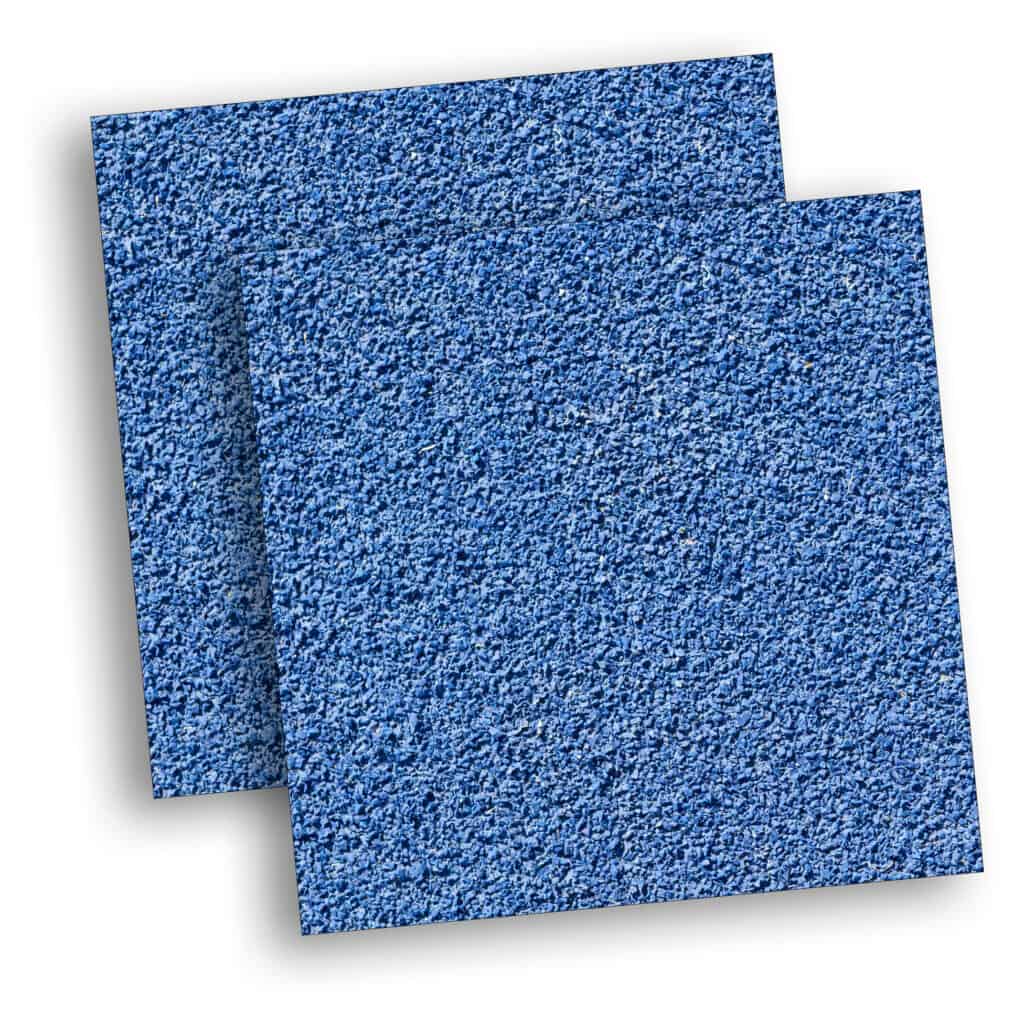

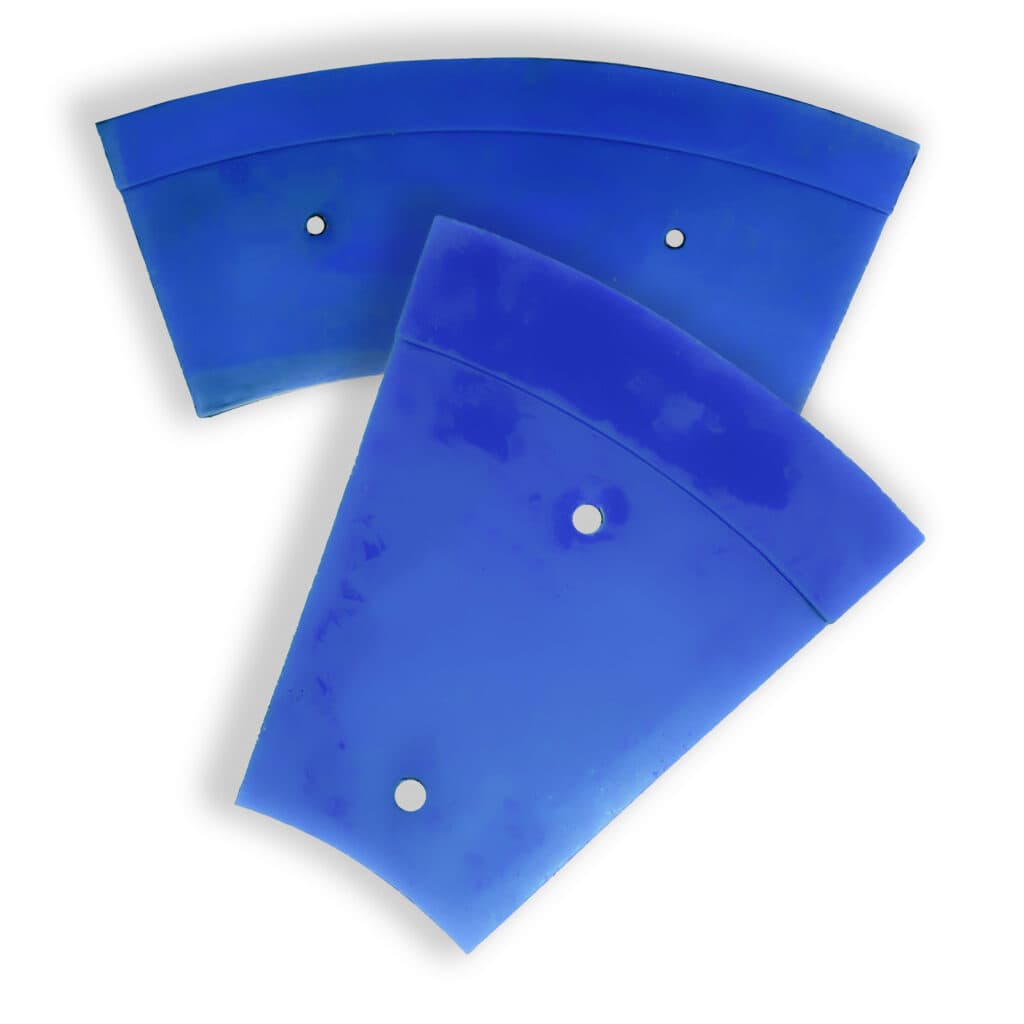

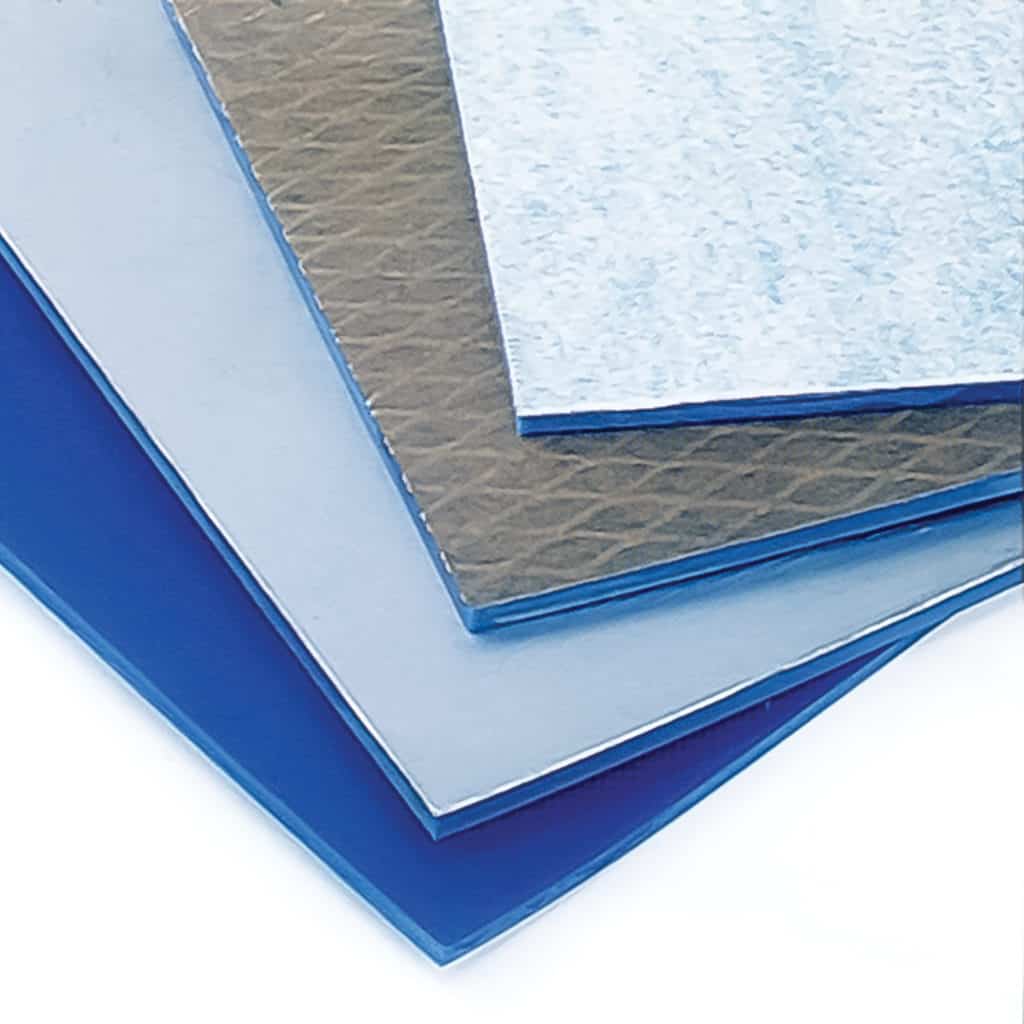

Versatile, Durable and Abrasion-Resistant Polyurethane

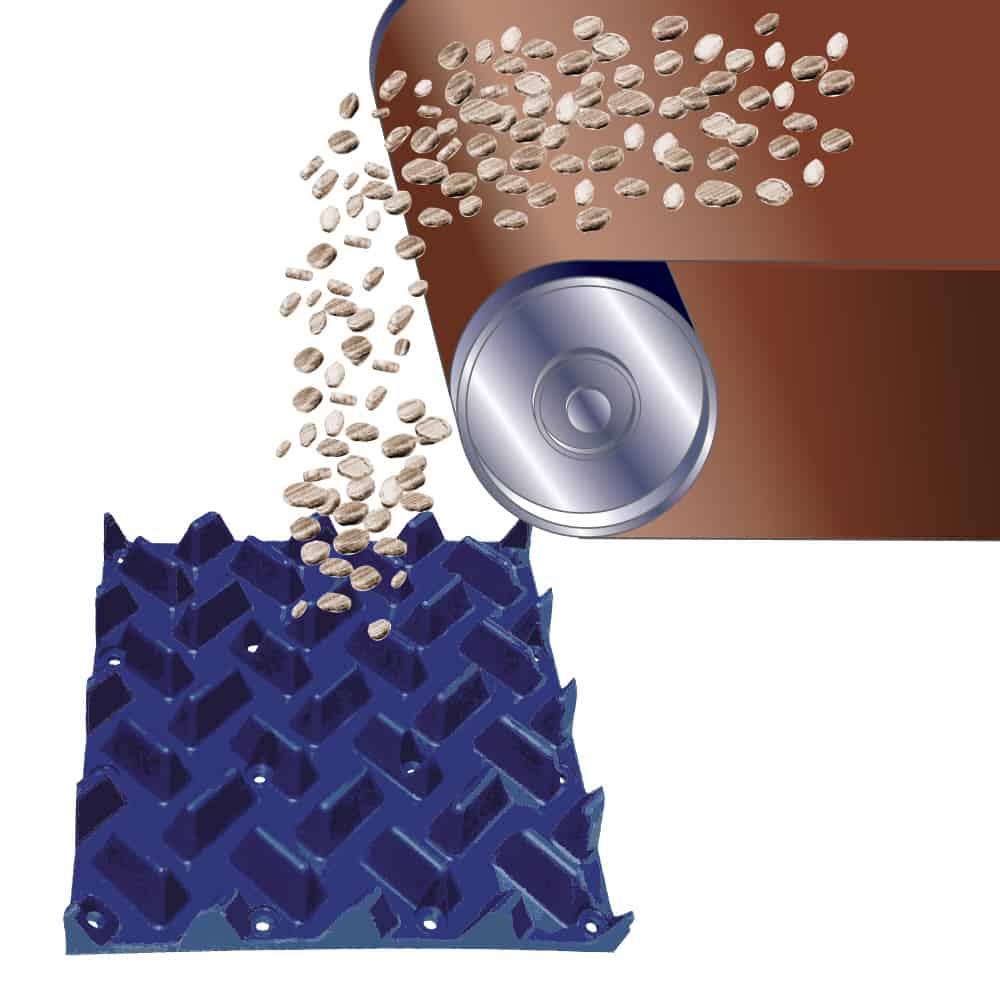

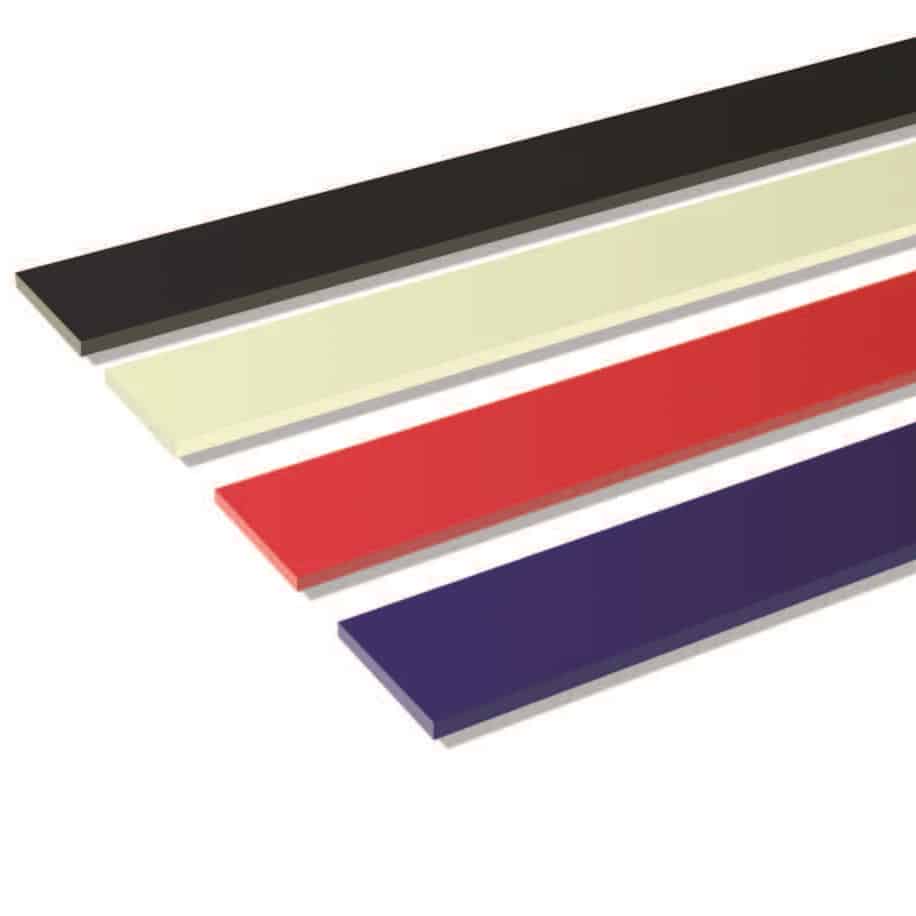

Diamondback® polyurethane liners and sheets are among the most versatile of all lining materials. A trademarked product manufactured only by Bailey-Parks, these polyurethane liners are available in a variety of standard sizes and hardnesses, providing outstanding resistance to impingement and frictional abrasion. Diamondback® urethane sheets meet FDA standards for dry food handling, and cushion grain, feed and other materials from breakage.

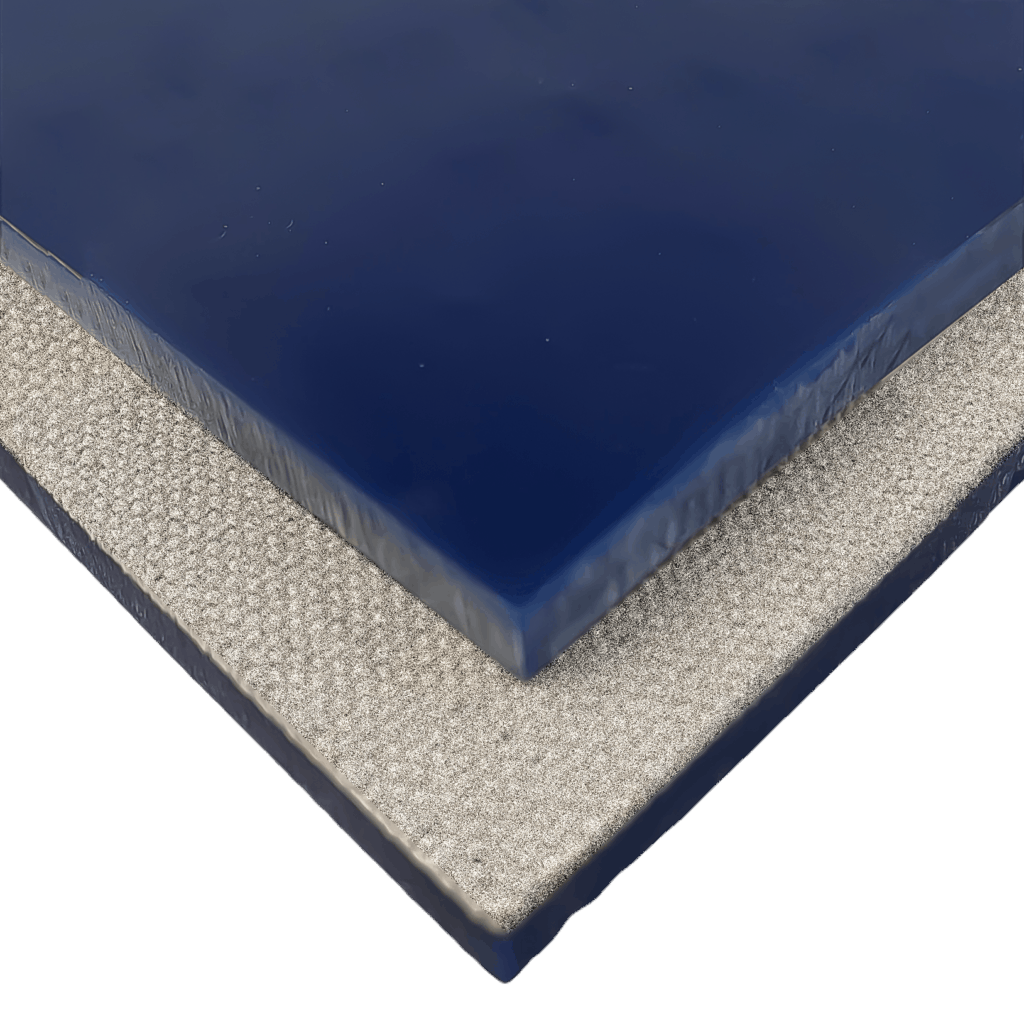

Strict quality control for a superior product

Each and every Diamondback® polyurethane sheet is produced using computerized casting and monitoring equipment. In addition to standard verification processes, Bailey-Parks checks every lot both during the pour and after the final cure to ensure ultimate tensile strength, percent elongation break at 100 and 300 percent modulus and durometer rating.