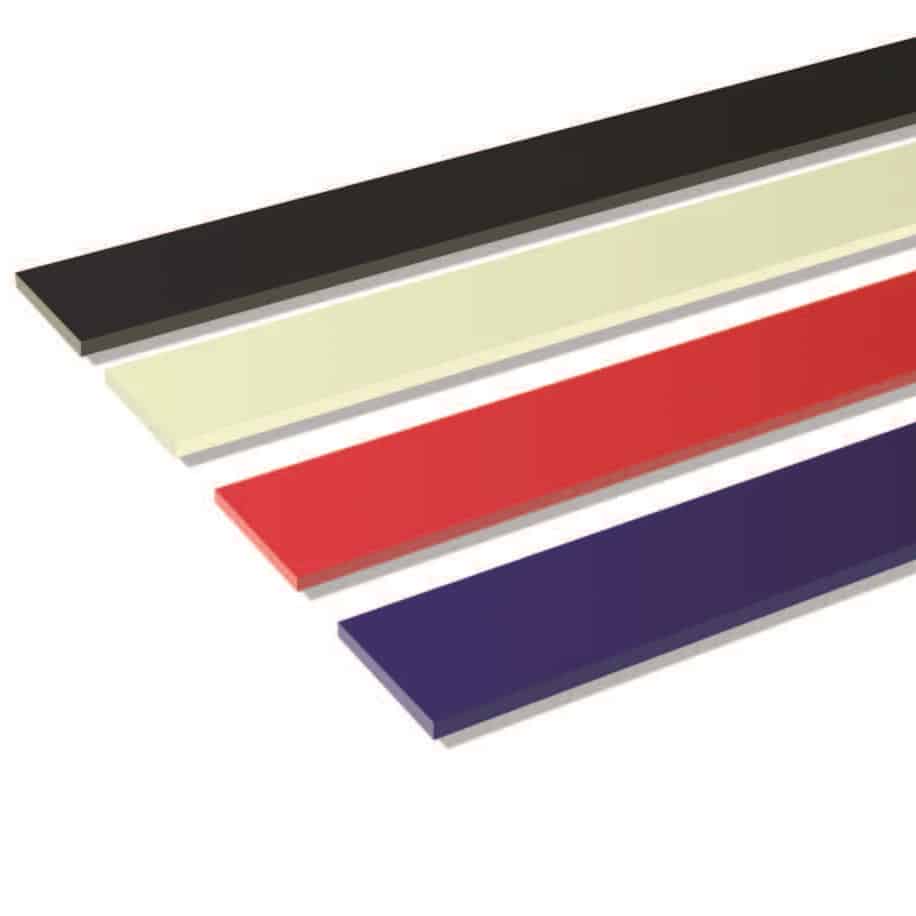

Diamondback® General Purpose Belt Wiper

General Purpose (GP) Conveyor belt wipers consist of Bailey-Parks standard Diamondback materials used in applications where FDA DRY products are required. The Diamondback GP belt wipers help clean away moist debris such as rock, gravel, sand, stone, and other substances processed on bulk material handling conveyors that can create a sticky build up. Bolted to the conveyor and easy to install on major brands, urethane belt wipers last far longer than metal, plastic, steel, or UHMW wiper alternatives. Typical belt wipers are an 85A, however, they can be produced in hardness from 65A-92A durometer, which ensures cut resistance and resiliency.

Specifications

Available sizes: widths from

6″- 12″ and

lengths up to 50′

Thickness: 1/2″ – 1″