Wedgie Bolt Urethane Fasteners

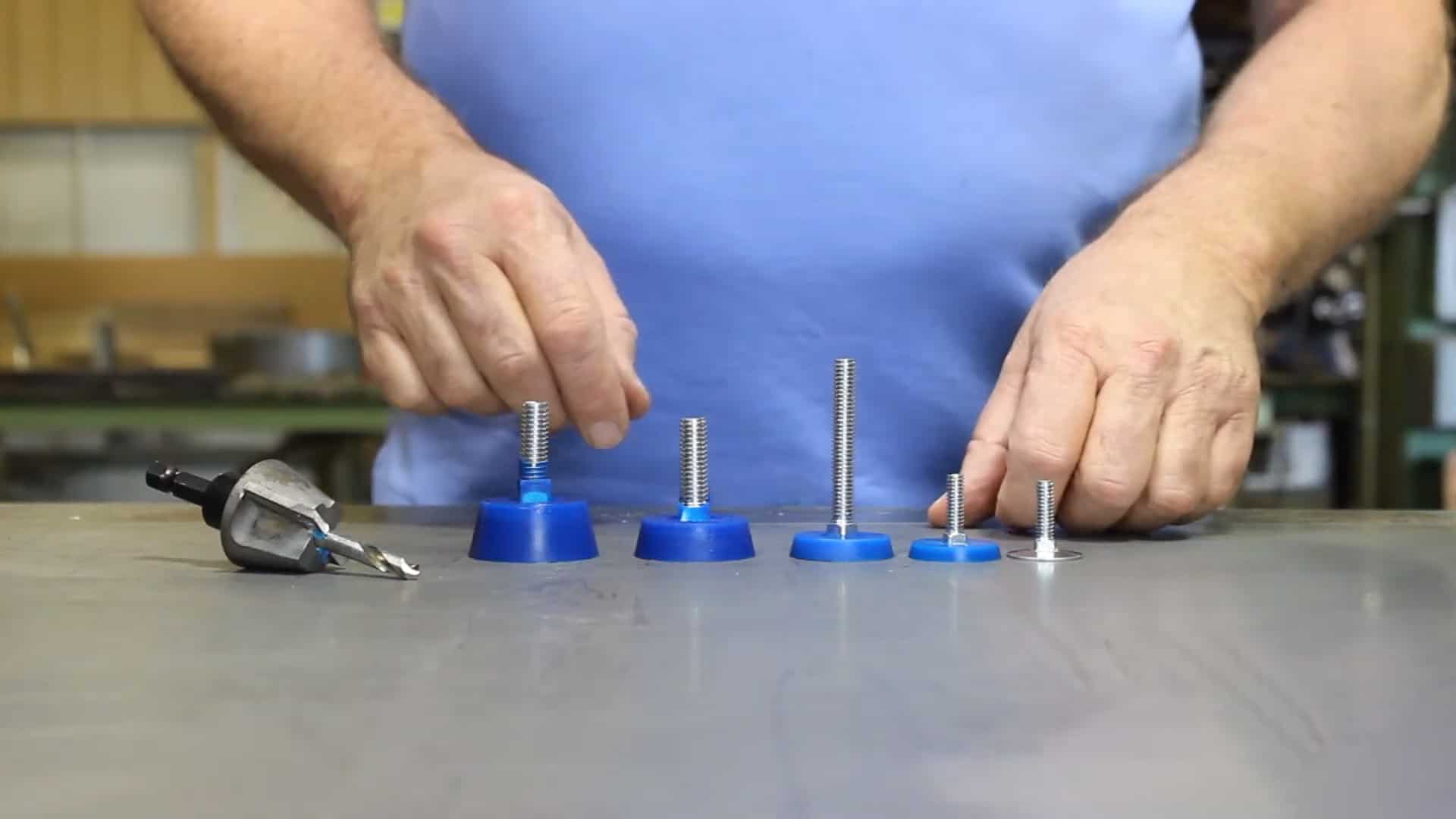

The Wedgie Bolt™ Urethane Fastening System offers the best, longest wearing fastening system available for use with urethane and other synthetic rubber products. The Wedgie Bolt™ is formulated with Bailey Parks’ tough Diamondback® urethane, known to outwear even heat treated alloy steel by a 6:1 margin.

Play Video

Advantages

Conventional metal bolts, even when countersunk, offer very little resistance to wear, and no resistance to leakage in applications involving liquid slurry. The Wedgie Bolt™, in addition to its superior wearability, has been pressure tested, with water, to 1200 PSI with no leakage.

Other Advantages

- Locking effect means that bolt will not slip against urethane once it has been countersunk

- Seals against urethane sheet, prohibiting seeping or leaking in wet applications without the use of messy sealants

- When properly installed there is no interruption to flow due to protruding bolt head

- Reduces likelihood of fungus buildup in hole/bolt crevice

- Designed to allow maximum use and wearability of urethane or other material being fastened

- “One-time” installation item – it should last as long as the sheet itself, reducing need for maintenance inspection

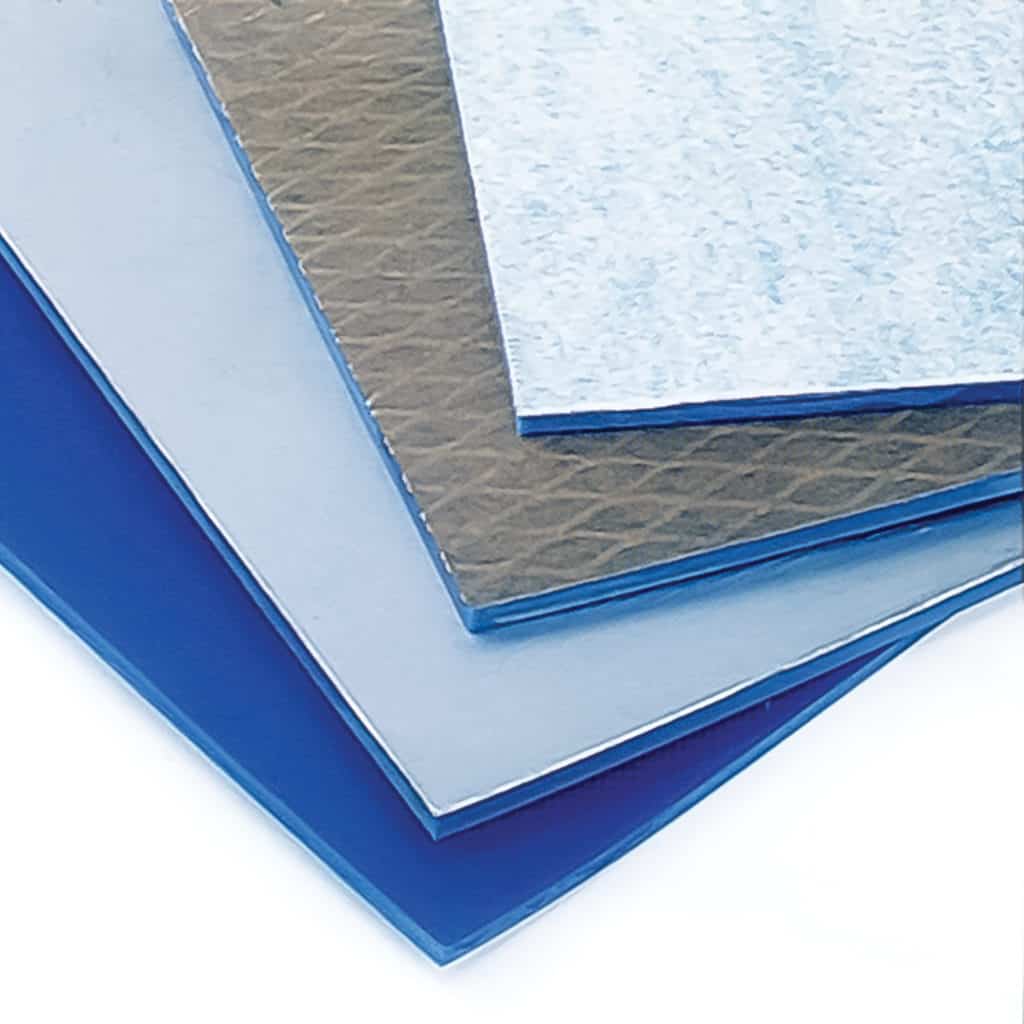

- Available sizes for use with sheet thickness 1/4″ – 1″