Fracking Sand Transport

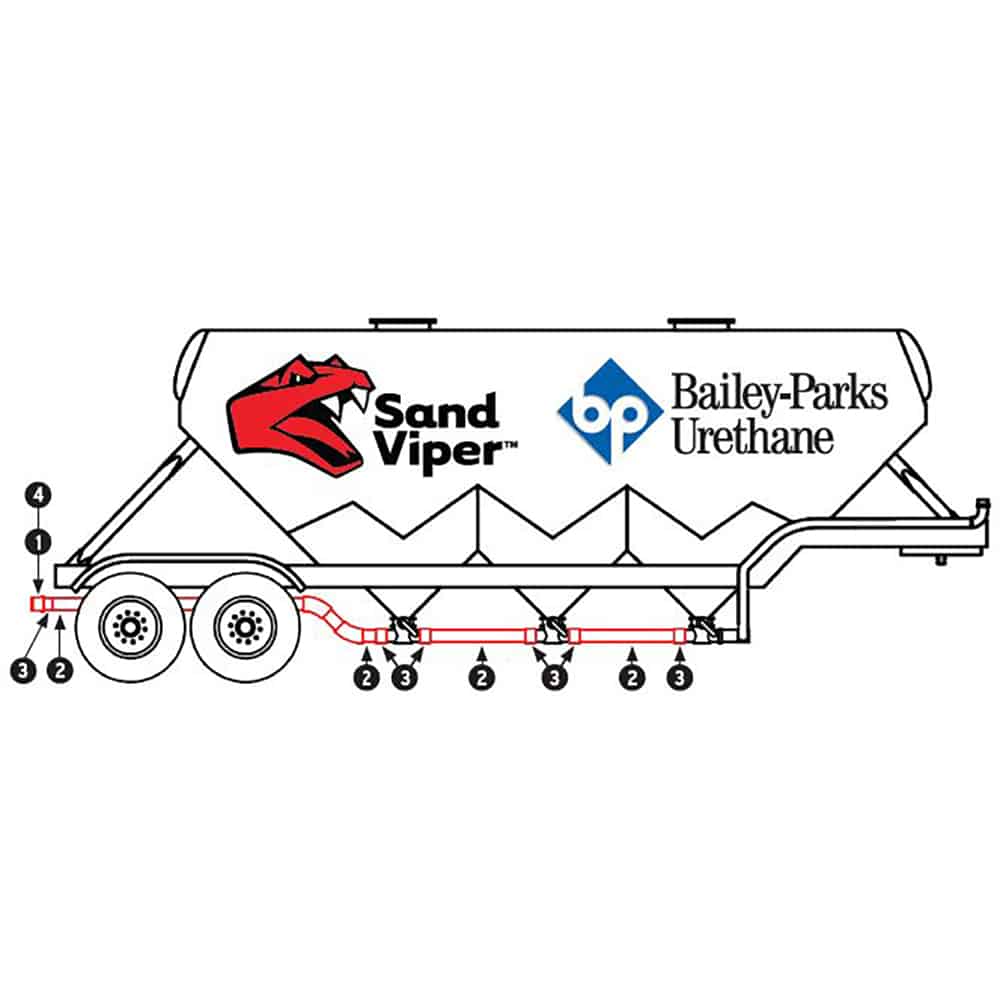

The Bailey-Parks Sand Viper™ piping system is a long-lasting polyurethane piping system originally designed to replace the aluminum pipes on trailers that transport fracking sand.

Incredibly wear-resistant, urethane lasts significantly longer than aluminum or steel in harsh conditions like those encountered in the oil, gas, and mining industries. The Sand Viper is made of a specialized composite urethane that has a hardness of 93A durometer and enhanced self-healing features so that it is optimized to resist intense abrasion such as that caused by frac-sand.

Customizable for a variety of applications

Originally designed for the oil and gas industry, the Sand Viper system can be adapted for a wide variety of applications involving the transport of caustic materials, such as those administered by the waste management industry.